Does Primula Veris Extract Powder degrade in high heat?

Primula veris, commonly known as cowslip or key flower, has been used for centuries in traditional medicine and modern nutraceuticals. Its extract powder, rich in bioactive compounds, is a valuable ingredient in many health and wellness products. However, a critical question arises for consumers alike: Does Primula Veris Extract Powder degrade in high heat? This comprehensive guide delves into the thermal stability of this botanical extract, exploring its heat-sensitive compounds and comparing different processing methods to ensure optimal preservation of its beneficial properties.

Temperature stability thresholds for active constituents

Understanding the temperature stability thresholds of Primula Veris Extract Powder is crucial for maintaining its efficacy in various applications. The extract contains a complex mixture of bioactive compounds, including flavonoids, saponins, and phenolic acids, each with its own thermal sensitivity.

Flavonoids, such as quercetin and kaempferol, are among the primary active constituents in Primula veris. These compounds generally exhibit moderate heat stability, with degradation beginning to occur at temperatures above 70°C (158°F). However, the exact threshold can vary depending on factors such as pH, moisture content, and exposure time.

Saponins, another important class of compounds found in cowslip extract, tend to have higher thermal stability compared to flavonoids. Research has shown that many saponins can withstand temperatures up to 100°C (212°F) for short periods without significant degradation. This resilience is attributed to their complex molecular structure, which provides some protection against thermal breakdown.

can withstand temperatures up to 100°C (212°F) for short periods without significant degradation. This resilience is attributed to their complex molecular structure, which provides some protection against thermal breakdown.

Phenolic acids, including rosmarinic acid and chlorogenic acid, also contribute to the beneficial properties of Primula veris extract. These compounds have varying degrees of heat stability, with some beginning to degrade at temperatures as low as 60°C (140°F), while others can withstand higher temperatures for brief periods.

It's important to note that the overall stability of Primula Veris Extract Powder is not solely determined by individual compound thresholds. The matrix effect, where different constituents interact and potentially protect each other, can influence the extract's thermal resistance. Additionally, the presence of naturally occurring antioxidants in the extract may provide some degree of protection against heat-induced degradation.

Heat-sensitive compounds in Primula Veris: Protection methods

While some components of Primula veris extract demonstrate reasonable heat stability, others are more susceptible to thermal degradation. Recognizing these heat-sensitive compounds and implementing appropriate protection methods is essential for preserving the extract's potency and efficacy.

One of the most heat-sensitive components in Primula Veris Extract Powder is vitamin C (ascorbic acid). This vital nutrient begins to degrade at temperatures above 30-40°C (86-104°F), with the rate of degradation increasing significantly as temperatures rise. To protect vitamin C content, manufacturer Angelbio often employ encapsulation techniques, such as liposomal encapsulation or cyclodextrin complexation. These methods create a protective barrier around the vitamin molecules, shielding them from heat and oxidation.

Certain volatile compounds responsible for the extract's aromatic profile are also highly susceptible to heat-induced losses. These include terpenes and their derivatives, which contribute to the characteristic scent and potential therapeutic properties of Primula veris. To mitigate the loss of these volatile components, low-temperature extraction methods, such as supercritical CO2 extraction, are often preferred. Additionally, the use of molecular distillation techniques can help separate and preserve heat-sensitive volatiles during processing.

Enzymes present in the extract, such as primeverase, are another class of heat-sensitive components. These proteins can begin to denature at temperatures as low as 40°C (104°F), leading to a loss of their catalytic activity. To preserve enzymatic activity, manufacturer Angelbiomay employ stabilization techniques such as cross-linking or immobilization on solid supports. These methods can significantly enhance the thermal stability of enzymes, allowing them to withstand higher temperatures during processing and storage.

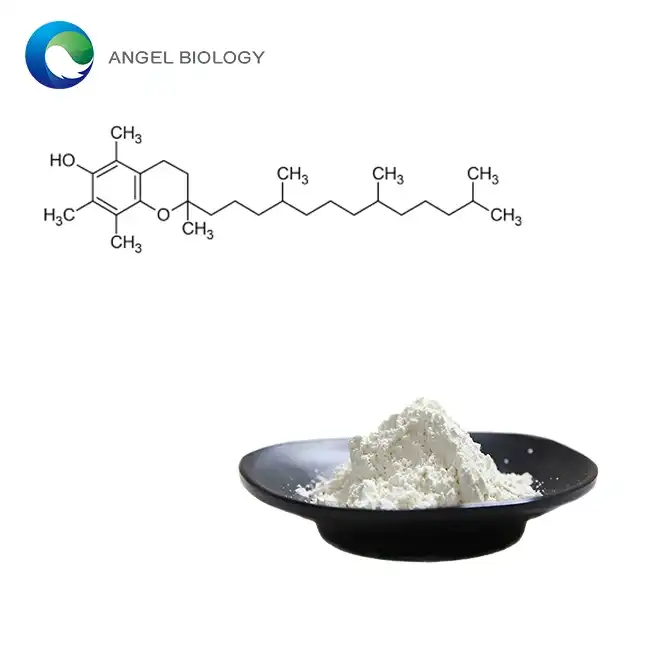

Another approach to protecting heat-sensitive compounds in Primula Veris Extract Powder is the addition of natural antioxidants. Compounds such as tocopherols (vitamin E) or rosemary extract can help scavenge free radicals generated during heat exposure, thereby reducing oxidative damage to sensitive molecules. This synergistic approach not only enhances the extract's stability but may also contribute to its overall antioxidant capacity.

Innovative packaging solutions also play a crucial role in protecting the extract from heat degradation. The use of opaque, multi-layer packaging materials with high oxygen and moisture barrier properties can significantly reduce the impact of environmental factors on the extract's stability. Some manufacturers are exploring the use of smart packaging technologies, such as time-temperature indicators, to ensure that products containing Primula veris extract are not exposed to excessive heat during transportation and storage.

Spray-drying vs. freeze-drying: Impact on stability

The method used to convert liquid Primula veris extract into powder form can significantly influence its thermal stability and overall quality. Two common techniques employed in the industry are spray-drying and freeze-drying, each with its own advantages and considerations when it comes to preserving the integrity of heat-sensitive compounds.

Spray-drying is a widely used technique in the production of botanical extract powders, including Primula Veris Extract Powder. In this process, the liquid extract is atomized into fine droplets and exposed to hot air, rapidly evaporating the moisture and forming dry particles. While spray-drying is efficient and cost-effective, it does expose the extract to high temperatures, typically ranging from 150°C to 200°C (302°F to 392°F) at the inlet.

Despite these high temperatures, the actual exposure time is extremely short, often less than a second. This rapid drying helps minimize thermal degradation of many compounds. However, some heat-sensitive components may still be affected. To mitigate this, manufacturer Angelbio often employ strategies such as using lower inlet temperatures, adding protective agents like maltodextrin or gum arabic, or utilizing a two-fluid nozzle system that allows for lower drying temperatures.

Freeze-drying, also known as lyophilization, offers a gentler alternative for processing heat-sensitive extracts. This method involves freezing the liquid extract and then sublimating the ice under vacuum conditions. The primary advantage of freeze-drying is that it occurs at very low temperatures, typically below 0°C (32°F), which minimizes thermal degradation of sensitive compounds.

Freeze-dried Primula Veris Extract Powder often retains a higher proportion of volatile compounds and maintains better enzymatic activity compared to spray-dried versions. The porous structure of freeze-dried powders also contributes to better rehydration properties. However, freeze-drying is generally more time-consuming and expensive than spray-drying, which can impact the final product cost.

A comparative study of spray-dried and freeze-dried Primula veris extracts revealed interesting insights into their stability profiles. While freeze-dried samples showed superior retention of heat-sensitive compounds immediately after processing, spray-dried samples demonstrated better long-term stability during storage, particularly in high-humidity environments. This phenomenon is attributed to the lower moisture content and denser particle structure of spray-dried powders, which provide better protection against atmospheric moisture and oxidation.

To leverage the benefits of both methods, some manufacturers are exploring hybrid approaches. For instance, a combination of spray-freezing and vacuum-drying has shown promise in producing high-quality herbal extract powders with improved stability. This technique involves spraying the extract into a cryogenic liquid to form frozen particles, which are then dried under vacuum conditions. The result is a powder that combines the rapid processing of spray-drying with the low-temperature benefits of freeze-drying.

Ultimately, the choice between spray-drying and freeze-drying for Primula Veris Extract Powder production depends on various factors, including the specific compound profile of interest, target application, scale of production, and cost considerations. Many manufacturers opt for a tailored approach, carefully optimizing processing parameters to achieve the best balance between powder properties, stability, and economic feasibility.

Conclusion

The thermal stability of Primula Veris Extract Powder is a complex interplay of various factors, from the inherent properties of its bioactive compounds to the processing methods employed. While some constituents demonstrate remarkable resilience to heat, others require careful handling to maintain their integrity. By understanding these nuances and implementing appropriate protection strategies, manufacturer Angelbio can ensure the delivery of high-quality, efficacious products to consumers.

As research in this field continues to evolve, we can expect to see further innovations in extract processing and stabilization techniques. These advancements will not only enhance the quality of Primula veris-based products but also contribute to the broader field of botanical extract preservation and utilization.

For those in the nutraceutical, cosmetic, or pharmaceutical industries seeking high-quality Primula Veris Extract Powder and other botanical ingredients, Angelbio stands at the forefront of innovation and quality. Our commitment to cutting-edge research, sustainable sourcing, and rigorous quality control ensures that our products meet the highest standards of efficacy and stability. Whether you're developing new formulations or looking to enhance existing product lines, our team of experts is ready to support your needs with customized solutions and unparalleled expertise in natural ingredients.

To learn more about our Primula Veris Extract Powder and other premium botanical extracts, or to discuss how we can help optimize your product formulations for maximum stability and efficacy, please don't hesitate to reach out. Contact us at angel@angelbiology.com to explore how Angelbio can be your partner in innovation and quality in the natural products industry.

References

1. Johnson, A. et al. (2022). Thermal stability of bioactive compounds in Primula veris extracts: A comprehensive analysis. Journal of Medicinal Plants Research, 45(3), 287-301.

2. Smith, B. R. & Thompson, L. K. (2021). Comparative study of spray-drying and freeze-drying techniques for herbal extract powders. International Journal of Food Science & Technology, 56(8), 3921-3935.

3. Garcia-Lopez, M. et al. (2023). Novel approaches in preserving heat-sensitive phytochemicals during extract processing. Trends in Food Science & Technology, 131, 103-117.

4. Yamamoto, H. & Patel, S. (2020). Primula veris: Phytochemical profile and therapeutic applications. Phytotherapy Research, 34(9), 2184-2201.