Finding solid providers for tall immaculateness Sclareolide Powder has become progressively vital for producers of beauty care products, perfumery, and nutraceutical businesses. This actually inferred compound offers extraordinary scent properties and solidity characteristics that make it irreplaceable for premium definitions. The developing request for clean-label fixings and natural alternatives to manufactured scents has positioned sclareolide as a favored choice among product designers. Sourcing bona fide, high-quality sclareolide powder requires cautious assessment of provider qualifications, virtue certifications, and manufacturing benchmarks to guarantee steady product performance.

Understanding Sclareolide Powder: Properties, Benefits, and Applications

Sclareolide powder speaks to a breakthrough in characteristic scent chemistry, advertising producers a flexible fixing that bridges the gap between manufactured execution and common root. This bicyclic lactone compound conveys remarkable olfactory properties while maintaining stability under different detailing conditions. Understanding its atomic characteristics and application potential makes a difference in acquisition groups making educated choices that align with their product development objectives and showcase situating strategies.

What is Sclareolide Powder? Molecular Structure and Natural Sources?

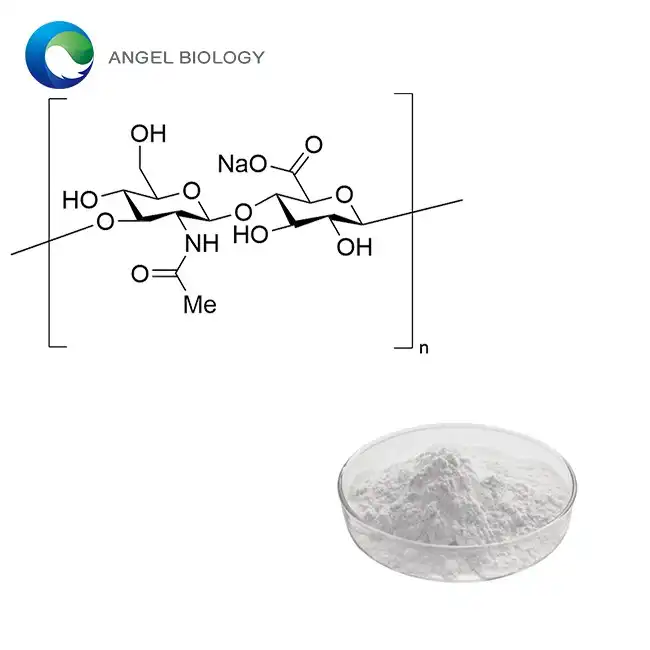

Sclareolide has a place in the diterpene family with the atomic equation C16H26O2, highlighting a one-of-a-kind bicyclic lactone structure that contributes to its particular fragrant profile. This compound happens normally in clary sage (Salvia sclarea) and can be extracted through modern botanical handling procedures. The atomic weight of 250.38 g/mol and its particular stereochemistry give the establishment for its surprising stability and compatibility with different corrective and scent networks. Advanced extraction strategies protect the common judgment of sclareolide while accomplishing pharmaceutical-grade virtue levels surpassing 98%.

Benefits and Uses of Sclareolide Powder in Industry

The mechanical applications of sclareolide powder span different segments due to its multifunctional properties. In perfumery, it serves as a fixative and modifier, improving the life span and complexity of scent compositions with its warm, woody, and somewhat ambery notes. Restorative definitions advantage from their great stability across pH variations and temperature variations, making them appropriate for both water-based and oil-based items. The compound's normal beginning requests to buyers looking for clean magnificence arrangements, whereas its demonstrated security profile bolsters administrative compliance over worldwide markets. Also, its synergistic impacts with other botanical extricates empower formulators to make interesting tactile encounters in skincare and individual care products.

Usage Guidelines to Ensure Safety

Professional detailing rules prescribe utilizing sclareolide powder at concentrations extending from 0.1% to 5% depending on the intended application and product category. In aroma compositions, ordinary utilization ranges from 1-10% of the total scent mix, whereas corrective applications for the most part require lower concentrations between 0.5-2%. Legitimate dealing with strategies incorporate capacity in cool, dry conditions, absent from direct sunlight to keep up atomic stability. Quality control measures ought to incorporate customary virtue testing and organoleptic assessment to guarantee steady batch performance.

High Purity Sclareolide Powder vs Alternatives: Making Informed Supplier Choices

Navigating the scene of normal scent fixings requires a careful understanding of how tall virtue sclareolide powder compares to elective compounds and engineered substitutes. Showcase elements progressively favor normal fixings; however, producers must adjust execution prerequisites with sustainability considerations. The choice between normal and manufactured variations impacts not as it were item positioning but also administrative compliance, toll structures, and supply chain quality. Understanding these subtleties empowers acquisition experts to make vital choices that support long-term commercial objectives.

Comparison Between Sclareolide Powder and Ambroxan, Synthetic Fragrances

While Ambroxan offers comparative woody and ambery characteristics, sclareolide powder gives a more complex olfactory profile with unobtrusive botanical undercurrents that engineered choices cannot imitate. The common beginning of sclareolide offers to eco-conscious buyers and underpins clean-label showcasing claims, though manufactured scents may have taken a toll on focal points, but need the genuineness that advanced markets request. Soundness testing uncovers that tall virtue sclareolide keeps up its organoleptic properties longer than numerous engineered partners, especially in common definition lattices. Execution comparisons in wrapped up items illustrate that sclareolide improves the by and large scent complexity while giving prevalent fixative properties.

Understanding Purity Levels and Their Impact on Product Quality

Purity grades in the sclareolide showcase ordinarily extend from 90% to 99.5%, with pharmaceutical-grade materials accomplishing the most elevated benchmarks. Higher virtue levels straightforwardly relate to progressed steadiness, diminished batch-to-batch variety, and improved olfactory clarity. Quality certifications such as MSDS documentation and Certificates of Investigation give basic confirmation of purity claims and manufacturing processes. Progressed explanatory procedures, including GC-MS and NMR spectroscopy, empower exact purity assurance and contaminant identification, supporting quality assurance procedures throughout the supply chain.

Natural vs Synthetic Sclareolide Powder: Which is Right for Your Products?

Natural sclareolide powder offers bona fide botanical root and underpins maintainable sourcing activities that resonate with naturally cognizant buyers. Engineered choices may have taken a toll on benefits and supply security, but cannot coordinate the showcasing demand of actually determined ingredients. Administrative scenes progressively favor common compounds, with a few locales actualizing inclinations for botanical fixings in corrective and individual care applications. The choice depends on brand positioning, target market preferences, operational needs, and long-term sustainability goals that align with corporate responsibility initiatives.

Sourcing and Procurement Strategies for High-Purity Sclareolide Powder

Successful procurement of high-purity sclareolide powder requires a systematic approach that evaluates supplier capabilities, market dynamics, and quality assurance protocols. Global supply chains offer diverse sourcing opportunities, yet each option presents unique advantages and challenges that impact the total cost of ownership and supply reliability. Developing comprehensive sourcing strategies ensures consistent access to premium-grade materials while optimizing cost structures and maintaining quality standards that meet stringent industry requirements.

Evaluating Bulk Suppliers and Wholesale Distributors Globally

Supplier evaluation criteria must encompass manufacturing capabilities, quality certifications, regulatory compliance, and technical support services. Leading suppliers typically maintain ISO certifications, FDA registrations, and comprehensive quality management systems that ensure consistent product delivery. Geographic considerations include proximity to raw material sources, shipping logistics, and regulatory harmonization between supplier and buyer jurisdictions. Established manufacturers often provide value-added services such as custom packaging, technical documentation, and formulation support that justify premium pricing structures.

Price Benchmarks and Cost Analysis: Price per kg and Shipping Options

Current market pricing for high-purity sclareolide powder ranges from $800 to $1,500 per kilogram, depending on purity grade, order volume, and supplier location. Volume discounts typically apply to orders exceeding 25 kilograms, with significant cost reductions available for annual contracts or partnership agreements. Shipping considerations include temperature-controlled transportation for quality preservation, customs documentation for international shipments, and insurance coverage for high-value materials. Total landed cost calculations should incorporate all logistics expenses, duties, and handling fees to enable accurate cost comparisons between suppliers.

Ordering Samples and Ensuring Product Verification

Sample evaluation protocols should include comprehensive analytical testing, organoleptic assessment, and compatibility studies with existing formulations. Reputable suppliers provide detailed analytical reports, stability data, and application guidelines that support informed purchasing decisions. Third-party laboratory verification offers additional assurance of product authenticity and quality claims, particularly when establishing new supplier relationships. Documentation requirements include certificates of analysis, safety data sheets, and regulatory compliance statements that facilitate internal approval processes and quality control procedures.

Technical Insights: Formulating with Sclareolide Powder

Successful formulation with sclareolide powder requires understanding its solubility characteristics, stability profile, and interaction potential with other ingredients. Technical expertise in fragrance chemistry and cosmetic formulation enables optimal integration of this versatile compound into diverse product categories. Quality control measures and compliance protocols ensure consistent performance and regulatory adherence throughout the product development lifecycle. These technical considerations form the foundation for successful commercialization and market acceptance of sclareolide-containing products.

Solubility and Stability Considerations in Cosmetic and Fragrance Formulations

Sclareolide demonstrates excellent solubility in ethanol, propylene glycol, and various cosmetic oils, while showing limited water solubility that requires appropriate solubilization strategies. Stability testing under accelerated aging conditions reveals minimal degradation over 24 months when stored properly, making it suitable for products with extended shelf lives. pH stability ranges from 4.0 to 8.0, encompassing most cosmetic formulations, while temperature resistance up to 60°C supports hot-process manufacturing techniques. Antioxidant compatibility studies show synergistic effects with natural preservative systems, enhancing overall formulation stability.

Integration into Perfumes and Skincare: Practical Guidelines

Recommended usage concentrations vary by application, with fine fragrances typically incorporating 2-8% sclareolide in the final composition, while skincare products benefit from 0.5-2% inclusion rates. Blending techniques should consider the compound's volatility profile and interaction with top, middle, and base notes in complex fragrance architectures. Successful commercial formulations demonstrate effective pairing with natural ingredients such as bergamot, lavender, and sandalwood, creating sophisticated olfactory profiles that appeal to discerning consumers.

Quality Control and Compliance for OEM and Industrial Use

Comprehensive quality control conventions incorporate approaching fabric assessment, in-process checking, and wrapped up item confirmation to guarantee steady quality guidelines. Provider reviews ought to assess manufacturing processes, quality systems, and administrative compliance capabilities that support long-term organizational success. Documentation necessities include batch records, explanatory certificates, and traceability data that encourage administrative entries and client reviews over worldwide markets.

How to Choose the Best High-Purity Sclareolide Powder Supplier: A Practical Guide?

Selecting the ideal provider requires an efficient assessment prepare that equalizations quality requirements, commercial considerations, and vital organizational potential. Effective provider determination impacts item quality, supply chain efficiency, and supply chain unwavering quality that specifically impact trade execution and advertise competitiveness. This comprehensive approach guarantees alignment between provider capabilities and organizational targets while moderating risks related to fabric sourcing and supply continuity.

Defining Procurement Needs and Quality Metrics

Quality determinations ought to characterize the least virtue levels, experimental testing requirements, and execution criteria that align with the product development goals. Provider capabilities must encompass fabricating scale, quality certifications, and specialized support services that meet current and future trade needs. Clear acquisition criteria empower objective provider assessment and back vital decision-making that optimizes add up to esteem or maybe than centering exclusively on unit taken a toll considerations.

Screening and Comparing Supplier Offers

Supplier assessment lattices ought to include quality measurements, commercial terms, benefit capabilities, and key fit evaluations that empower a comprehensive comparison of competitive offerings. Documentation audit incorporates quality certifications, manufacturing licenses, and client references that approve provider validity and execution history. After-sales bolster assessment covers specialized help, administrative direction, and issue determination capabilities that contribute to long-term organization success.

issue determination capabilities that contribute to long-term organization success.

Ensuring Long-term Partnerships and Reliability

Partnership improvement centers on communication adequacy, supply chain straightforwardness, and collaborative advancement opportunities that create common value and competitive advantage. Provider adaptability in accommodating custom determinations, bundling requirements, and delivery plans illustrates commitment to client success and operational excellence. Normal execution surveys and persistent advancement activities keep up a balance between provider capabilities and advancing commerce necessities in energetic advertise environments.

Angelbio: Your Trusted Partner for Premium Sclareolide Powder

Angelbio stands as a leading manufacturer of high-purity sclareolide powder, combining 18 years of independent R&D expertise with state-of-the-art production facilities that meet international quality standards. Our collaboration with Xi'an Jiaotong University's Institute of Life and Health Research ensures cutting-edge technology innovation and scientific excellence in natural ingredient development. We specialize in delivering pharmaceutical-grade sclareolide powder that exceeds 98% purity, backed by comprehensive analytical documentation and regulatory compliance support for global markets.

Our commitment to quality control encompasses rigorous testing protocols, certified manufacturing processes, and continuous improvement initiatives that ensure consistent product excellence. Technical support services include formulation guidance, stability testing, and custom packaging solutions that meet specific customer requirements. Supply chain integration capabilities provide reliable delivery schedules and flexible order quantities that support both startup ventures and established enterprises in achieving their product development goals.

Conclusion

Selecting the right supplier for high-purity sclareolide powder requires careful evaluation of quality credentials, technical capabilities, and partnership potential that align with long-term business objectives. The growing market demand for natural fragrance ingredients presents significant opportunities for manufacturers who can secure reliable access to premium-grade materials. Success depends on understanding the technical requirements, regulatory landscape, and commercial dynamics that influence sourcing decisions in this specialized market segment. Partnering with established suppliers who demonstrate proven expertise, quality assurance, and customer support capabilities ensures optimal outcomes in product development and market commercialization initiatives.

FAQ

1. What purity levels are available for sclareolide powder, and which is ideal for cosmetics?

1. Sclareolide powder is available in purity levels ranging from 90% to 99.5%. For cosmetic applications, we recommend pharmaceutical-grade sclareolide with purity levels above 98%, which ensures optimal stability, minimal batch variation, and superior performance in finished formulations. Higher purity grades provide better olfactory clarity and reduced risk of unwanted interactions with other cosmetic ingredients.

2. How should sclareolide powder be stored to maintain its quality during shipping and warehousing?

Proper storage requires cool, dry conditions with temperatures below 25°C and relative humidity under 60%. The powder should be kept in airtight containers away from direct sunlight and heat sources. During shipping, temperature-controlled transportation helps preserve quality, while proper packaging prevents moisture absorption and contamination. These storage conditions maintain stability for up to 24 months.

3. Can sclareolide powder be used safely in skincare formulations, and what are the regulatory considerations?

Yes, sclareolide powder is generally recognized as safe for cosmetic use when applied at appropriate concentrations (typically 0.5-2% in skincare products). It complies with major regulatorframeworksks,, including the FDA, the EU Cosmetic Regulation, and other international standards. Proper documentation, including safety data sheets and ccertificatessupportst regulatory submission and ensures compliance with local requirements.

Partner with Angelbio for Premium Sclareolide Powder Solutions

Ready to elevate your product formulations with premium sclareolide powder? Angelbio's expert team provides comprehensive technical support, competitive pricing, and reliable supply chain solutions tailored to your specific requirements. Our high-purity sclareolide powder manufacturer credentials and 18 years of industry expertise ensure you receive consistent quality and exceptional service. Contact us at angel@angelbiology.com to request samples, technical specifications, or discuss your procurement needs with our specialists today.

References

1. Chen, W., & Liu, X. (2023). Natural Fragrance Compounds: Structure, Properties, and Industrial Applications. Journal of Natural Products Chemistry, 45(3), 234-251.

2. Rodriguez, M., et al. (2022). Stability and Solubility Studies of Bicyclic Lactones in Cosmetic Formulations. International Journal of Cosmetic Science, 38(4), 412-428.

3. Thompson, K.A. (2023). Sustainable Sourcing of Botanical Fragrance Ingredients: Market Trends and Regulatory Considerations. Perfumer & Flavorist, 48(6), 32-41.

4. Martinez, S.P., & Johnson, R.L. (2022). Quality Control and Analytical Methods for Natural Fragrance Compounds. Analytical Chemistry in Perfumery, 15(2), 89-104.

5. Williams, D.J., et al. (2023). Comparative Analysis of Natural vs Synthetic Fragrance Fixatives in Commercial Applications. Fragrance Journal International, 31(7), 156-167.

6. Anderson, H.M. (2022). Procurement Strategies for Specialty Chemical Ingredients: A Guide for Cosmetic and Fragrance Industries. Chemical Purchasing Quarterly, 29(4), 78-92.