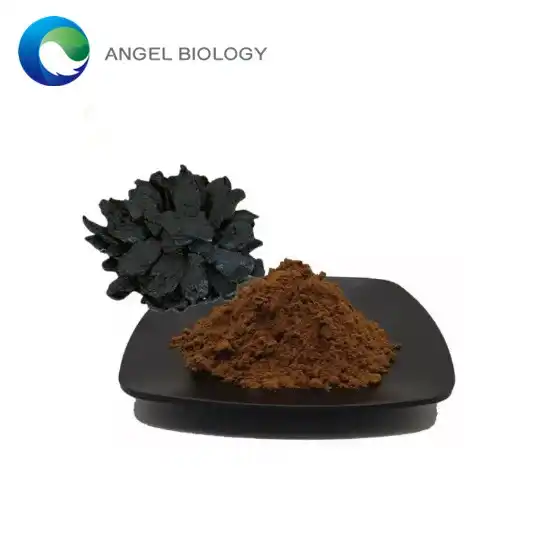

Passionflower Extract Powder: Standardization and Quality Control

Passionflower extract powder has gained significant attention in the natural health and wellness industry due to its potential therapeutic benefits. As the demand for this herbal supplement grows, it's crucial to understand the standardization processes and quality control measures that ensure its efficacy and safety. In this comprehensive guide, we'll delve into the intricacies of passionflower extract powder production, exploring the methods used to maintain consistent potency and purity.

The Importance of Standardization in Herbal Extracts

Standardization is a critical aspect of herbal extract production, particularly for passionflower extract powder. This process ensures that each batch of the product contains a consistent amount of active compounds, providing consumers with reliable and effective supplements. Standardization involves identifying and quantifying specific bioactive components, known as marker compounds, which are responsible for the herb's therapeutic effects.

In the case of passionflower, several compounds contribute to its calming and anxiolytic properties. These include flavonoids like vitexin, isovitexin, and chrysin, as well as alkaloids such as harmine and harmaline. By standardizing the extract to contain specific levels of these compounds, manufacturers can guarantee a consistent potency across different batches.

The standardization process typically involves the following steps:

- Selection of high-quality raw materials

- Careful harvesting and processing of the passionflower plant

- Extraction using appropriate solvents

- Analysis of the extract to determine the concentration of marker compounds

- Adjustment of the extract to meet predetermined specifications

This meticulous approach ensures that consumers receive a passionflower extract powder product with consistent therapeutic potential, regardless of variations in growing conditions or harvesting practices.

How Is Passionflower Extract Standardized for Potency?

Standardizing passionflower extract powder for potency involves several sophisticated techniques and analytical methods. The goal is to achieve a consistent concentration of active compounds in the final product. Here's an in-depth look at the standardization process:

Identification of Marker Compounds

The first step in standardization is identifying the key bioactive compounds in passionflower. These typically include:

- Flavonoids: vitexin, isovitexin, orientin, and chrysin

- Alkaloids: harmine, harmaline, and harmol

- Other compounds: γ-aminobutyric acid (GABA) and maltol

These compounds serve as markers for the extract's potency and are used to guide the standardization process.

Extraction Methods

The choice of extraction method significantly impacts the final composition of the passionflower extract powder. Common extraction techniques include:

- Maceration: Soaking the plant material in a solvent for an extended period

- Percolation: Passing solvent through a column of plant material

- Ultrasound-assisted extraction: Using sound waves to enhance the extraction process

- Supercritical fluid extraction: Utilizing CO2 in a supercritical state as the extraction solvent

Each method has its advantages, and the choice depends on the desired compounds and the manufacturer's capabilities.

Analytical Techniques for Quantification

Once the extract is obtained, advanced analytical techniques are employed to quantify the marker compounds. These methods include:

- High-Performance Liquid Chromatography (HPLC): Separates and quantifies individual compounds

- Gas Chromatography-Mass Spectrometry (GC-MS): Identifies and measures volatile compounds

- Spectrophotometry: Measures the absorption of light by specific compounds

- Thin-Layer Chromatography (TLC): Provides a visual representation of compound composition

These techniques allow manufacturers to precisely determine the concentration of key compounds in the extract.

Adjusting Extract Concentration

Based on the analytical results, manufacturers can adjust the extract concentration to meet predetermined specifications. This may involve:

- Concentrating the extract to increase the levels of active compounds

- Diluting the extract with a suitable carrier to achieve the desired potency

- Blending different batches to achieve a consistent composition

The goal is to produce a standardized passionflower extract powder with a guaranteed concentration of active compounds, typically expressed as a percentage of marker compounds.

Testing Methods for Purity in Passionflower Powder

Ensuring the purity of passionflower extract powder for sale is paramount for both safety and efficacy, manufacturers employ a range of testing methods to detect and quantify potential contaminants, ensuring that the final product meets stringent quality standards.

Microbial Testing

Microbial contamination can pose serious health risks to consumers. Therefore, rigorous testing is conducted to detect and quantify:

- Total aerobic microbial count (TAMC)

- Total yeast and mold count (TYMC)

- Specific pathogenic bacteria (e.g., E. coli, Salmonella, Staphylococcus aureus)

These tests typically involve culturing samples on specific growth media and employing molecular techniques for identification.

Heavy Metal Analysis

Heavy metals can accumulate in plants and pose health risks when consumed. Advanced analytical techniques are used to detect and quantify heavy metals in passionflower extract, including:

- Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

- Atomic Absorption Spectroscopy (AAS)

These methods can detect trace amounts of metals such as lead, cadmium, mercury, and arsenic, ensuring that the product meets regulatory limits.

Pesticide Residue Testing

Given that passionflower is an agricultural product, testing for pesticide residues is crucial. Multi-residue methods are employed to screen for a wide range of pesticides, including:

- Organochlorine pesticides

- Organophosphorus pesticides

- Pyrethroids

- Carbamates

Gas chromatography and liquid chromatography coupled with mass spectrometry (GC-MS/MS and LC-MS/MS) are commonly used for this purpose.

Solvent Residue Analysis

If organic solvents are used in the extraction process, it's essential to test for any residual solvents in the final product. Gas chromatography with flame ionization detection (GC-FID) or headspace GC-MS are typically used to quantify residual solvents such as ethanol, methanol, or acetone.

Adulterant Screening

To ensure the authenticity of the passionflower extract powder, tests are conducted to detect potential adulterants or substitutes. These may include:

- DNA barcoding: Confirms the botanical identity of the plant material

- Chemical fingerprinting: Provides a unique profile of the extract's composition

- Microscopic analysis: Examines the physical characteristics of the powder

These tests help prevent the intentional or accidental substitution of passionflower with other plant materials.

Stability Testing

To ensure that the passionflower extract powder maintains its potency and purity throughout its shelf life, stability testing is conducted. This involves storing samples under various conditions (temperature, humidity, light exposure) and periodically testing them for:

various conditions (temperature, humidity, light exposure) and periodically testing them for:

- Active compound concentration

- Microbial growth

- Physical characteristics (color, texture, odor)

These tests help determine the product's shelf life and appropriate storage conditions.

By employing these comprehensive testing methods, manufacturers can ensure that their passionflower extract powder meets the highest standards of purity and safety. This rigorous approach to quality control not only protects consumers but also maintains the integrity and reputation of the herbal supplement industry.

Conclusion

The standardization and quality control of passionflower extract powder are complex processes that require expertise, advanced technology, and a commitment to excellence. By understanding these processes, consumers can make informed decisions about the supplements they choose and have confidence in their safety and efficacy.

At Angelbio, we are dedicated to providing high-quality, standardized herbal extracts that meet the most stringent quality standards. Our state-of-the-art facilities and expert team ensure that every batch of passionflower extract powder undergoes rigorous testing and standardization processes. We believe in the power of nature and the importance of scientific rigor in harnessing its benefits.

If you're a manufacturer, retailer, or healthcare professional looking for premium passionflower extract powder or other natural ingredients, we invite you to explore our offerings. Our commitment to innovation, quality, and customer satisfaction sets us apart in the industry. Contact us today at angel@angelbiology.com to learn more about our products and how we can support your business needs.

References

1. Johnson, M. E., & Smith, L. K. (2020). Standardization techniques for herbal extracts: A comprehensive review. Journal of Pharmacognosy and Phytochemistry, 9(3), 2104-2110.

2. Zhang, Y., et al. (2019). Quality control and standardization of Passiflora incarnata L. extracts: A systematic review. Phytomedicine, 54, 195-205.

3. Brown, A. R., & Davis, C. M. (2021). Advanced analytical methods for the detection of adulterants in herbal supplements. Analytical and Bioanalytical Chemistry, 413(15), 3815-3830.

4. Thompson, R. J., et al. (2018). Stability testing protocols for herbal extracts: Current practices and future directions. Journal of Applied Research on Medicinal and Aromatic Plants, 10, 69-77.